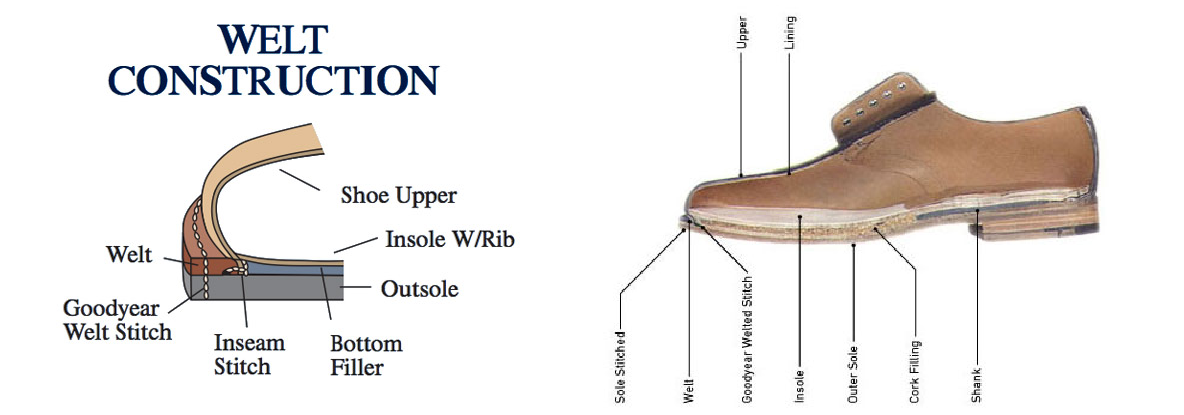

A highly renowned construction method considered to be one of the best for shoes constructed with a welt. A method for stitching outsole to welt and then the welt to outsole. Due to this two level stitching resoling is relatively easy to conduct. A goodyear welted shoe normally have a visible welt around the whole shoe. Goodyear welted shoes are easy to resole but due to multiple layers in construction it turns out relatively stiff.

Procedure

Gemming

The first step in the process is gemming the midsole. The actual gemming is normally a canvas strip cemented to the midsole as a point to attach the welt. In some cases the gemming is also attached by rapid stitching (read more about it here) to ensure bonding stability. Gemming can also be reffered to as rib.

Welt

A welt (flat leather or rubber strip for outsole attachement) is attached to the gemming by stitching. At the same time the stitching machine also attaches the upper to the midsole, through the gemming. The welt is normally at first attached with tack bars to keep position before sewn to the gemming. The tack bars usually stay in the shoe gemming after stitching. More on welts in the end of this article.

The gemming with welt is about 7 mm high which leaves a cavity between the gemming/welt and midsole. To even the surface a filler is used to cover this cavity and create cushioning. Normally corque or a corque mix is used but other materials are also common that allows for breathability. This is put in place with a mix of filler material and glue. Over time the filler usually collapses so upon resoling it´s common to also change filler.

With the upper lasted, the midsole gemmed and upper welted everything is joined together by two levels of stitching. First the “Insole seam” or “Goodyear welted stitch” running diagonally through the welt, gemming and upper. The second stitch is simply known as the “sole stitch. It´s common within the industry to interchange the name of the two stitches since there is no universal definition. The stitch is a lock-stitch, it will not unravel if any part breaks.

Apart from the Goodyear welted stitch the upper is also kept in place by the cement content of the filler securing the upper position and to not create a gap between the filler and inner sole.

The outsole can either be attached by a combination of the second sole stitch and cement or by only cement. Normally more dressed shoes feature the stitch and cement where with boots it´s not uncommon to only cement the outsole but having a midsole of EVA to which the welt is attached. This creates both a look and makes the outsole relatively easy to change upon need.

Welt (detailed)

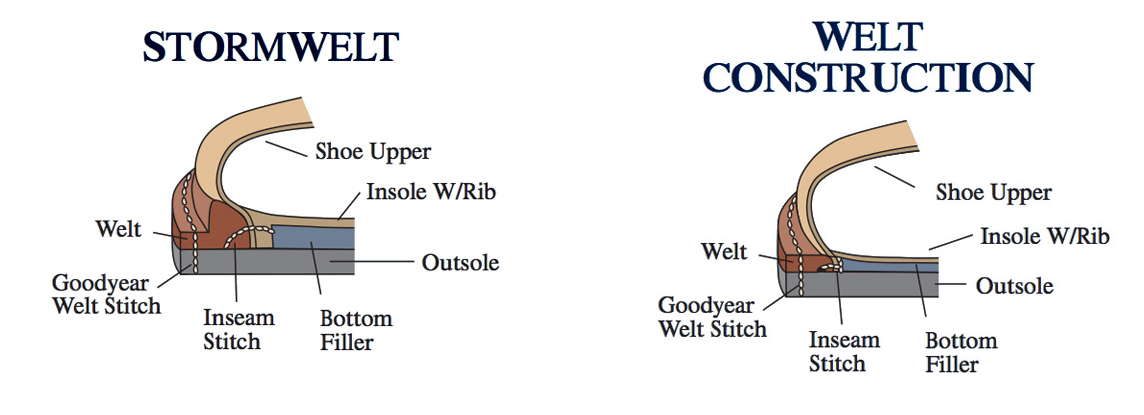

The welt is a strip of leather, plastic or rubber that runs alongside the edge of the outsole. Goodyear welted shoes are almost always using a leather welt since price is not the main focus for the product, rather durability and longevity. For full cemented constructions (read more here) it's common that the welt supplier makes a decorative stitch just for the look and welt is later on cemented to outsole. There is no real function in this, only to obtain a certain look, it´s but the original intent was to fasten the upper to the outsole.

Welts come in many different shapes and appearances but one commonly referred to is the “Storm welt”. it´s a normal welt but with a higher “wall” towards the upper to increase the water resistance. There are also further developments on this such as the Norwegian or Norveguese construction (read more about it here)

The outsole is then attached either by a cementing process or by stitching it to the welt, this is normally done with a rapid machine (read more about it here) but can also be done by hand.

History

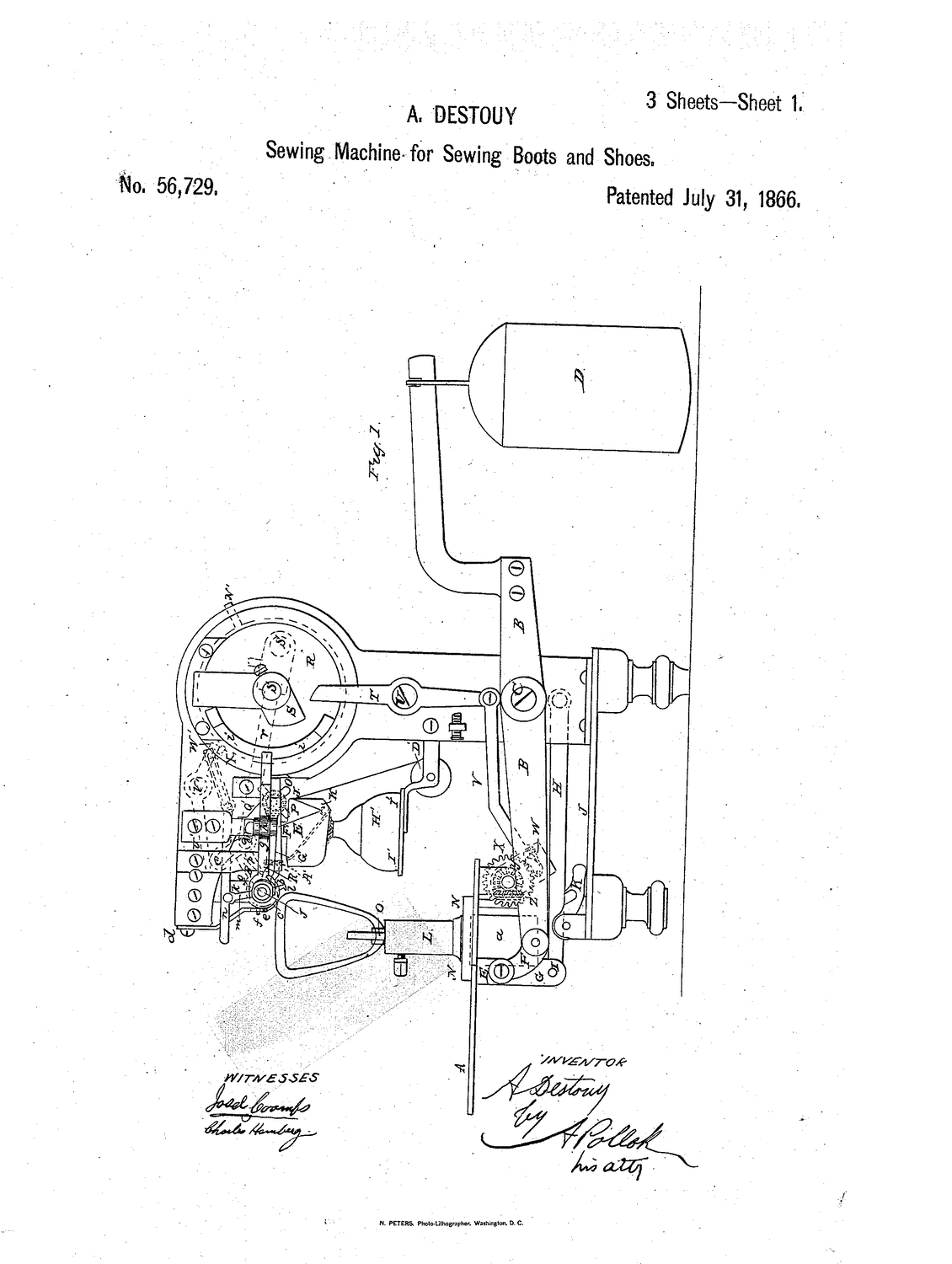

In 1860 a man named August Destouy developed a welt sewing machine which he in 1862 (or 1866) secured a patent of. He passed this patent to James Hanan, of the company Hanan & Sons shoe manufacturers of Brookyln. The patent was far from perfect and the machine faced many issues while running. Being a small company without the financial power or technical expertise Hanan decided to sell the patent.

At the time Charles Goodyear Jr, the son of Charles Goodyear accountable for the industrialization of the vulcanized process, was managing his fathers vulcanization patents, producing rubber goods and being president of America Shoe Tip Company.

In 1869 Hanan managed to interest Charles Goodyear Jr who purchased the patent and also convinced Hanan to come work for him. Goodyear Jr put Hanan in a team together with the technician Daniel Mills to improve upon the welt sewing machine and other practical machines.

In 1876 what we today know as the Goodyear machine saw daylight. The machine was capable of doing stitch and turn footwear but the main interest was the improved application of the welt stitching that made the success. Together with the electrification in the late 1800s challenging many traditional shoemakers to automatize their production the goodyear machinery was a good candidate. The reason for this was that a machine stitched shoe compared with a hand stitched was 5-6 times as cheap. Sewing that used to take 20 minutes by hand could take 20 seconds with a machine.

In the beginning of the 1900 an american company called United Shoe Machinery Limited collected: McKay Sewing Machine Company (inventor of Blake construction, read more about it here), Consolidated and McKay Lasting Machine Company, Goodyear Shoe Machinery Company, International Goodyear Shoe Machinery Company, Goodyear Shoe Machinery Company of Canada, Eppler Welt Machinery Company och Davey Pegging Machine Company under one umbrella. For some of the companies consolidated it was not considered a free choice but rather a necessity to protect the owners interest. The collection of knowledge in this way pushed the development of new more efficient methods further.

References

pimg-fpiw.uspto.gov/fdd/29/567/000/0.pdf

https://www.reddit.com/r/goodyearwelt/comments/1pl3ey/how_do_you_tell_if_a_shoeboot_is_welted/

http://dieworkwear.com/post/127005965439/goodyear-versus-handwelting

Comments